Bierbaum-Proenen - Fair workwear from tradition

The Cologne-based family business BP - Bierbaum-Proenen, founded in 1788, offers fair workwear solutions for every work situation and every body shape. The quality promise is the basis of the company's long history.

No matter whether they are employees in industry, energy supply, the trades, care, medicine, gastronomy or the food industry: They all rely on protective and work clothing from Bierbaum-Proenen. "Our claim is to offer the right clothing for every work situation and every body shape," says Carla Cacitti, who heads product development at BP. The products of the traditional company are characterised by their design, durability, functionality, very high wearing comfort and socially and ecologically compatible production. This quality promise is reflected in the BP claim: Feel the difference.

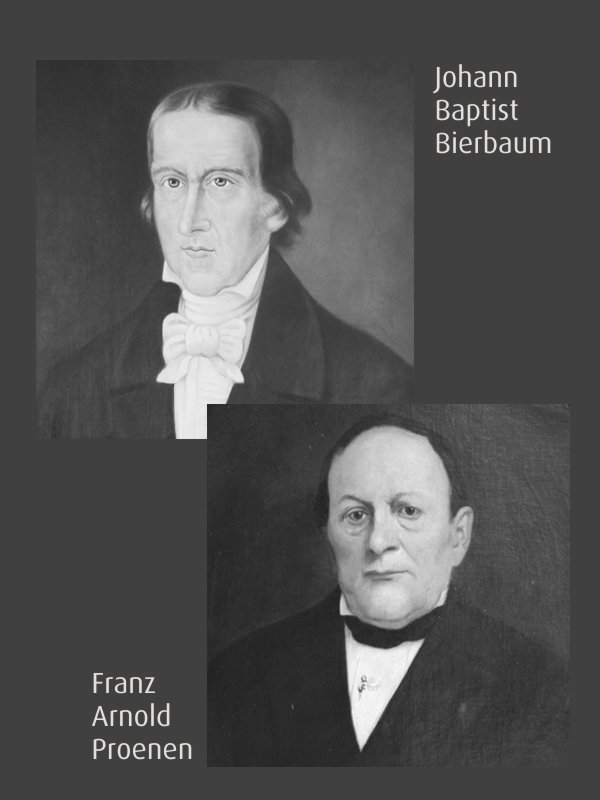

Bierbaum-Proenen's long company history began in 1788 with a promise: Only the best quality should pass over the counter of the linen shop. Founder Johann Baptist Bierbaum reminded his employees of this time and again. "My house is your guarantee" was how Bierbaum wooed his customers. And the young company had to show all the flexibility of a start-up to survive the first decades: In the turbulent years of the early 19th century, wine was also sold in the meantime in order to adapt to the changing conditions.

Workwear manufacturer in its seventh generation

At the end of the 19th century, Cologne gradually began to manufacture workwear. In 1914, Franz Proenen, the great-grandson of the founder, visited the Ford factories in Detroit. He was fascinated by the assembly line production. And he brought a new idea back with him to Germany: workwear from BP was to be produced on an assembly line. Not only could the quality be increased enormously through serial production, but the costs also fell considerably. Bierbaum-Proenen experienced enormous growth spurts.

Today, managing partner Harald Goost (pictured left) is the seventh generation to lead the family business. "We have only been able to survive on the market for so long because we think beyond the day and act in an economically sustainable manner," says Harald Goost. Against this background, it was logical that Bierbaum-Proenen added another promise to its quality promise in 2010: "We want to become the most sustainable workwear company."

More information about sustainability at BP.

Fair Workwear - Fair Wear Leader eleven times in a row

BP clothing had long since been produced in North Africa, Eastern Europe and Asia. The Cologne-based company's awareness of fair working conditions was therefore well-developed. But in 2010, the company decided to go one step further. BP became - as the first German manufacturer of workwear - a member of the Fair Wear Foundation (FWF). The independent multi-stakeholder initiative works to improve working conditions in the international clothing industry. Its standards are considered the highest in the industry. Gradually, all BP production sites were audited. In the meantime, BP has been awarded the FWF's highest distinction as a Fair Wear Leader eleven times in a row.

In view of the climate challenges, BP wants to calculate the carbon footprint for all products by 2030, identify and implement potential savings and offset unavoidable emissions in climate protection projects. BP is currently taking its first steps towards a circular economy with the first generation of circular polo shirts, which will be presented at the A+A trade fair. The shirts are made of ten percent recycled materials from production waste, the buttons are made of recycled cotton and the yarns are made of recycled polyester. The Circular Shirts are thus a commitment to the circular economy and contribute to waste reduction.

Sustainable workwear - quality and durability as the greatest contribution

The biggest contribution that the traditional company makes to sustainability is the quality and durability of its products. BP aims to produce the most durable workwear on the market. This means that customers do not have to buy new products every year. This saves many valuable resources. This claim does not only refer to fabrics, yarns and materials, but goes much further: for example, to the reduction of energy consumption and C0² emissions.

In addition to the quality promise and the sustainable manufacture of the products, the industrial washability of the clothing is a key argument for BP. The vast majority of BP products are suitable for industrial washing. This is very important because many companies - whether in elderly care and hospitals or many craftsmen, public utilities, energy suppliers or industrial companies - have their clothing professionally and hygienically reprocessed. Products from BP are convincing here with their very long durability.

More information about BP Workwear®.

1788 to 1831

Foundation and the challenges of the first decades

At the time, Cologne had a population of 30,000 and, due to the strict guild policies, allowed the young entrepreneur very little freedom. When he founded his business, Johann Baptist Bierbaum was 29 years old and a carpentry journeyman. He was not prepared to accept the confines imposed upon him by his guild. He successfully overcame all the obstacles that stood in the way of founding his business and, thanks to his perseverance, was made a Grand Burgher of the imperial city of Cologne on 27 August 1793. As a merchant, this was a tremendously important step as it entitled him to sell not only linen but also milled wool cloth and silk.

Leading the young company through the turmoil of the Napoleonic Wars, the economic embargo on the Rhineland and the Continental Blockade required a tremendous amount of skill and flexibility. In order to compensate for the shortfalls in the linen trade, Johann Baptist Bierbaum temporarily included wine in the product range.

From 1815 onwards, the company developed in leaps and bounds. The superior quality of the goods was a crucial factor in the success of this young, up-and-coming company.

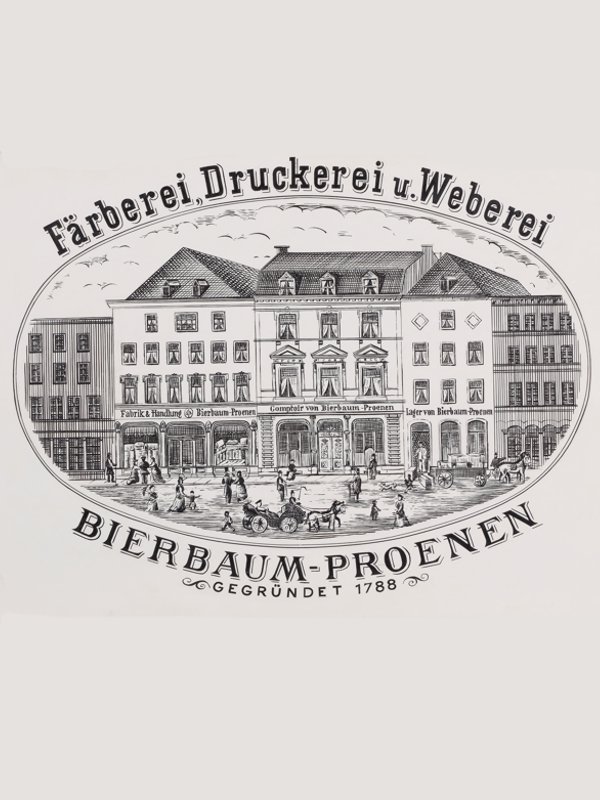

1832 to 1873

Up until this point, the company had been managed as a trading firm. However, it was now restructured and extended and, instead of merely trading goods, the Company started to produce linen and cotton fabrics, employing several hundred hand-weavers. It also had its own dye works and print shop for the in-house dyeing and printing of goods.

The company continued to expand and, after purchasing an adjacent building, extended its premises in Cologne’s Mühlengasse.

1874 to 1901

1902 to 1929

However, the First World War forced the ambitious company to put its plans on hold and assembly-line production was not introduced until 1929.

This production method required the streamlining of the entire range to concentrate on a small number of articles that were manufactured in large numbers and to a high standard by workers trained on the job.

Assembly-line production had a doubly positive effect: costs were reduced and the production quality was increased.

1930 to 1952

So they commissioned historian Dr. Helmut Vogt to examine this period of theTitel_Buch company history.

The resulting publication, “Bierbaum-Proenen 1929 – 1952. Ein Familienunternehmen während Weltwirtschaftskrise, Nationalsozialismus und Wiederaufbau” (Bierbaum-Proenen 1929- 1952. A Family Business during World Economic Crisis, National Socialism and Reconstruction), was published by J.P. Bachem in Cologne and is available from bookshops (ISBN 978-3-7616-2606-1). A summary of the book is available to download as a PDF file.

Although Bierbaum-Proenen GmbH & Co. KG financed the book, it’s important to note that neither the company nor its owners influenced its content.

1953 to 1970

At the same time, manufacturing techniques were further honed, which increased efficiency even more. The introduction of sophisticated quality management systems and the development of modern fits highlighted the high Quality standard of BP products.

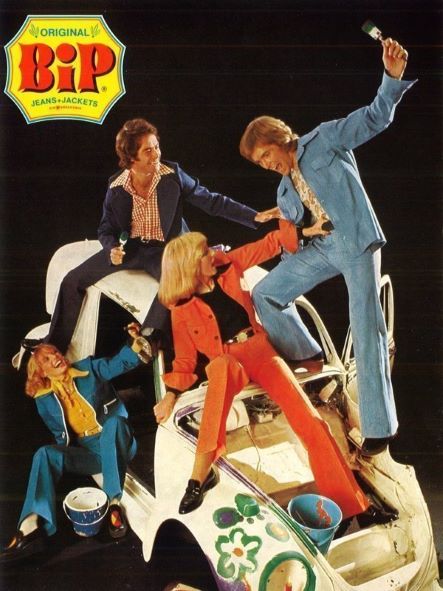

1971 to 1999

In line with continuing internationalisation, BP started to manufacture work clothing in Eastern Europe and the Far East. It gradually moved mass production to other countries, however, due to the high production efficiency, continued to produce goods in Germany until the 1990s. BP cooperated with foreign production partners and also built up its own production facilities in Portugal. This was followed by a factory in Mateur, Tunisia that, since 1997, has made a key contribution to further developing the company’s production expertise.

At the end of the 1980s, many companies began to discover the importance of a self-contained and coherent corporate identity. This also provided new opportunities for Bierbaum-Proenen: the company offered a large number of high-quality CI collections in a variety of different colours and fabrics from stock. The main consideration was always wearer comfort, and, as a result, BP mainly focused on the production of cotton-rich fabric containing 60% cotton and 40% polyester.

At the end of the 1990s, logistics were outsoured to an external service provider as the site in Cologne city centre that had been used since 1905 had become too small for the company’s complex logistical requirements.

2000 to 2015

BP became a member of the Partnership for Sustainable Textiles in 2015. The goal of this German government initiative is to ensure the social, environmental and economic standards throughout the entire production and retail chain of the clothing industry.

2016 to today

Improving sustainability

BP was awarded the status Fair Wear Leader for the tenth time. The new BPlus work clothing collection features a slim silhouette but, thanks to its stretch content, still offers great freedom of movement. BPlus is available in women’s and men’s fits and, with mix and match, is the ideal complement to the BP work clothing concept. The colors available and the many accessories in the shirt and outdoor section will be continuously added to and further developed.